A lightbox sign is one of the most effective ways for a business to grab attention and make a lasting first impression. These illuminated displays shine a literal spotlight on your brand, making you visible day and night. Whether you run a cozy café, a bustling retail shop, or a creative studio, understanding the world of lightbox signs can help you make a bright decision for your business.

This guide covers everything, from the basics of what a lightbox sign is and its benefits to the finer points of design, materials, and installation.

What is a Lightbox Sign?

A lightbox sign is an illuminated display panel built to promote a brand or message. It consists of a frame, or box, that holds a light source (these days, almost always LEDs) behind a translucent graphic face. The internal lighting makes the text and images on the front glow, dramatically increasing visibility around the clock.

Modern LED technology has made the lightbox sign more effective than ever. LEDs are brighter and far more energy efficient than the old fluorescent tubes, allowing for a vivid glow without a high power bill. For outdoor use, these signs are built to be weatherproof, often with sealed frames to protect the internal graphics from the elements. You’ll see them everywhere, from storefronts and restaurants to movie theater poster cases, where their bright presence cuts through the noise.

Why a Lightbox Sign Is a Bright Idea

The benefits of a lightbox sign go far beyond simple visibility. They can have a direct impact on your customer traffic, brand perception, and even your bottom line.

Attract More Customers: Great signage gets people in the door. According to a FedEx consumer survey, nearly 8 in 10 Americans (76%) have entered a store they had never visited before based on its sign alone. What’s more, 68% of consumers have made a purchase simply because a sign caught their eye. Complement your lightbox with a Rounded Sidewalk Sign to maximize curb appeal.

Boost Brand Perception: A quality sign signals a quality business. The same survey found that 68% of people believe a company’s signage reflects the quality of its products or services. A bright, professional lightbox sign instantly conveys credibility and can even generate word of mouth marketing, as three out of four consumers have told someone about a business just because of its impressive signage.

Work 24/7: A lightbox sign works for you long after the sun goes down, extending your advertising reach into the evening. Well lit environments can improve customer attraction by up to 30%, making your business a beacon for foot traffic after dark.

Energy and Cost Efficient: Modern LED technology is a game changer. LED lights use up to 80% less energy than traditional neon signs, which means you get brilliant illumination for a very low operating cost. Plus, LEDs are incredibly durable, often lasting 50,000 to 100,000 hours. That means your sign can shine brightly for over a decade with minimal maintenance.

Types of Lightbox Signs

Lightbox signs come in several forms, each suited for different applications and aesthetics. The main distinctions are based on construction and the materials used for the face.

Single Sided vs. Double Sided

A single sided lightbox sign has one illuminated face and a solid back, designed to be mounted flat against a wall. A double sided lightbox sign has graphics on both the front and back, making it perfect for projecting out from a building so it’s visible to people coming from either direction. For a non‑illuminated projecting alternative, consider a Rectangle Blade Sign. Double sided signs typically cost more due to the extra materials but can offer twice the exposure.

Face Materials

Acrylic Panel: This is a very common choice, featuring a rigid, translucent acrylic front. Graphics are often applied with printed vinyl. Acrylic offers sharp, vibrant images and excellent durability.

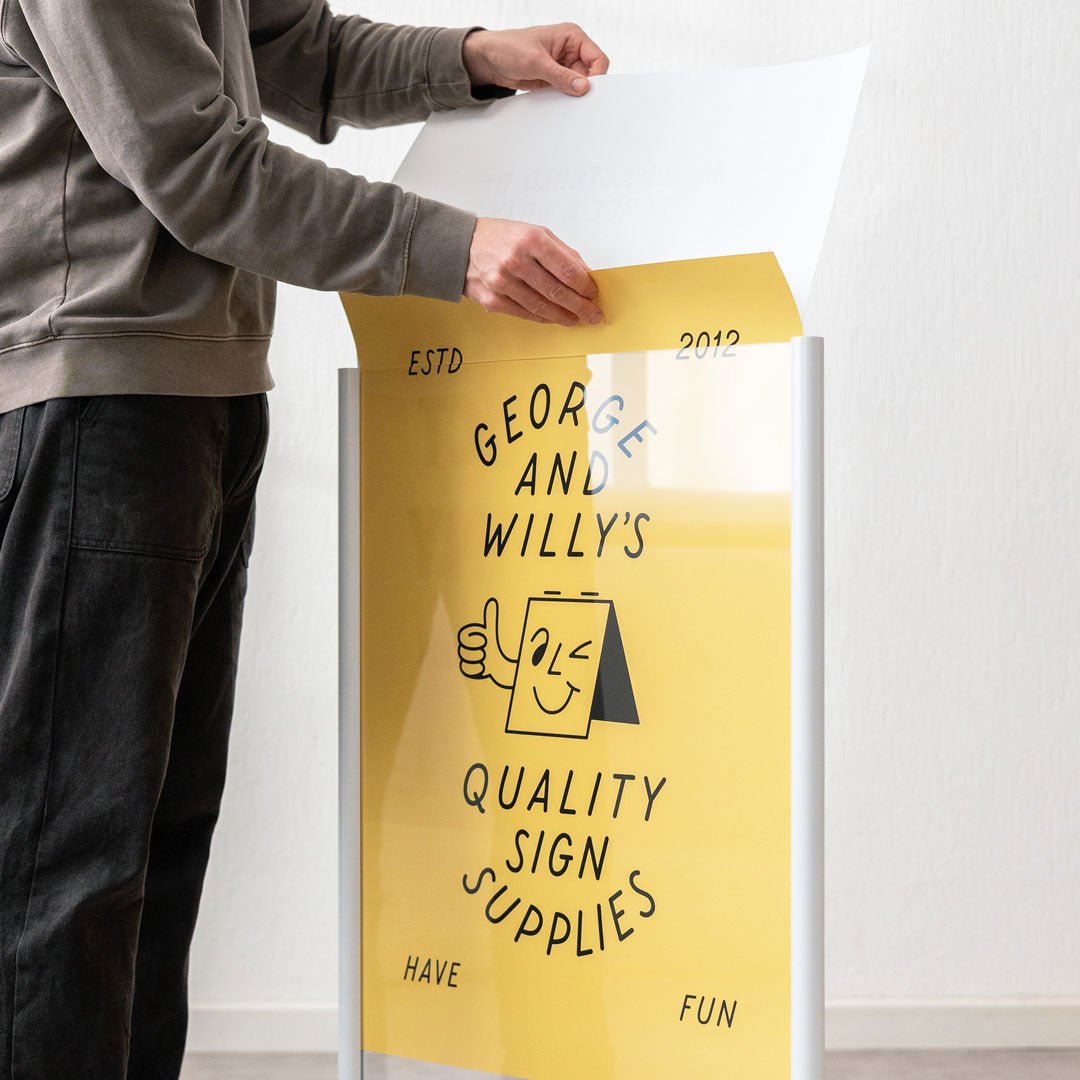

Fabric (SEG): Fabric lightbox signs use a stretched fabric graphic with a silicone edge that tucks into a slim frame, known as SEG (Silicone Edge Graphics). This creates a seamless, frameless look and allows for easy, tool free graphic swaps, making it popular for large indoor displays like trade show booths.

Tension PVC: A budget friendly option for very large signs, this type uses a PVC banner material stretched within a frame. While very bright, the lighting can sometimes be slightly uneven.

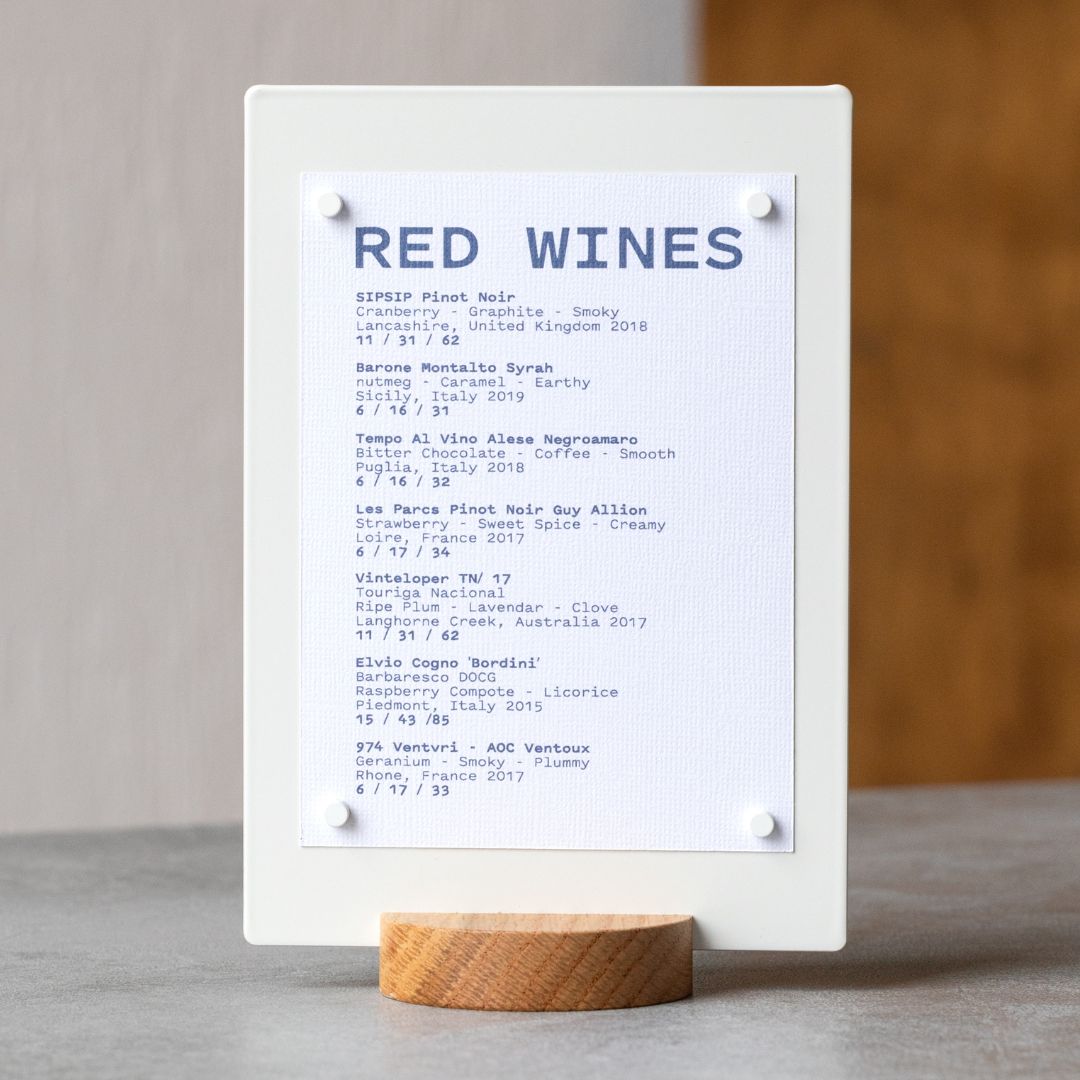

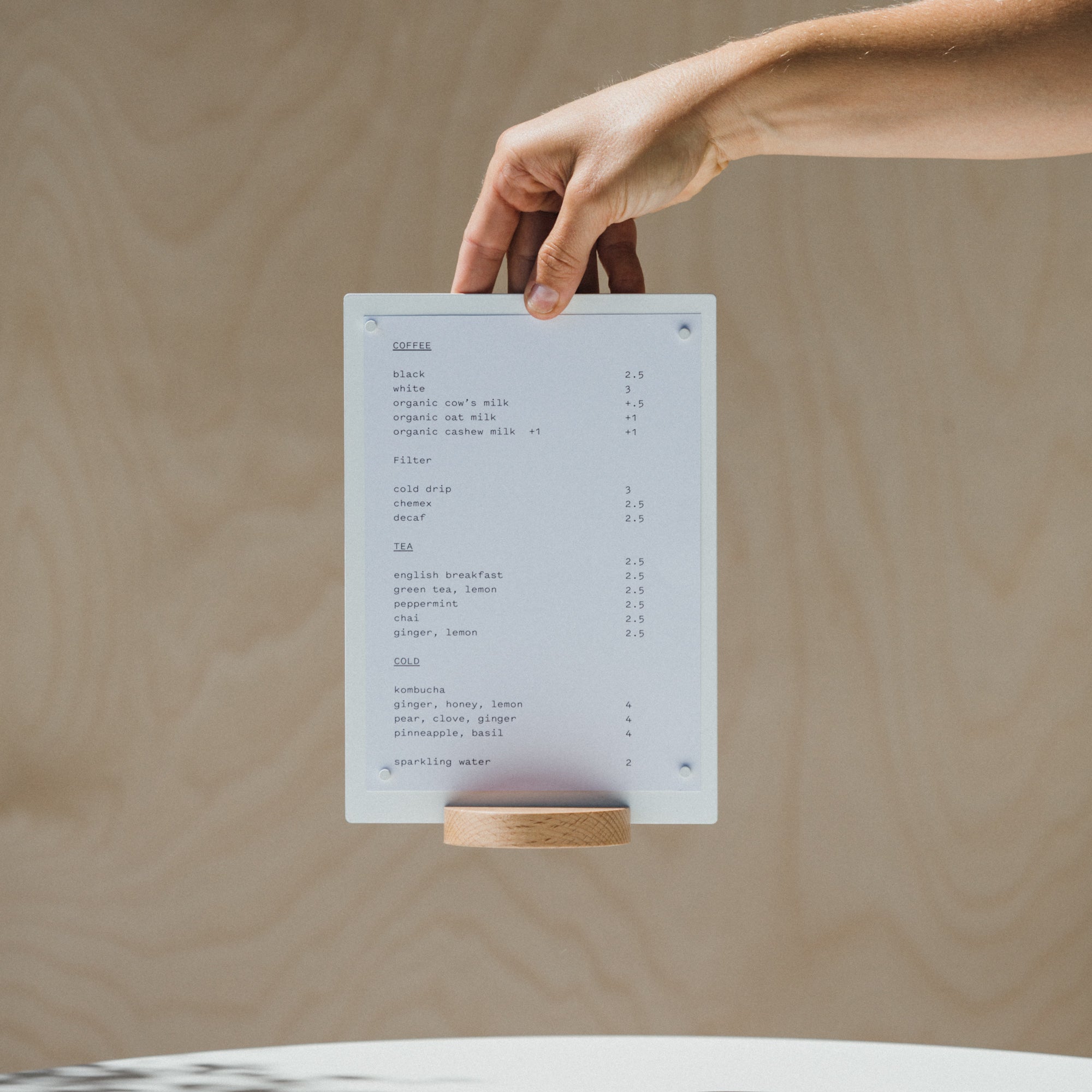

For businesses looking for a timeless and durable option, a classic acrylic face in a powder coated aluminum frame, like the George & Willy Round Light Box Sign, offers a perfect blend of style and resilience.

Designing Your Lightbox Sign

Effective lightbox sign design is about balancing aesthetics with readability. The goal is to create a sign that not only looks great but also communicates its message in a split second.

Branding and Messaging

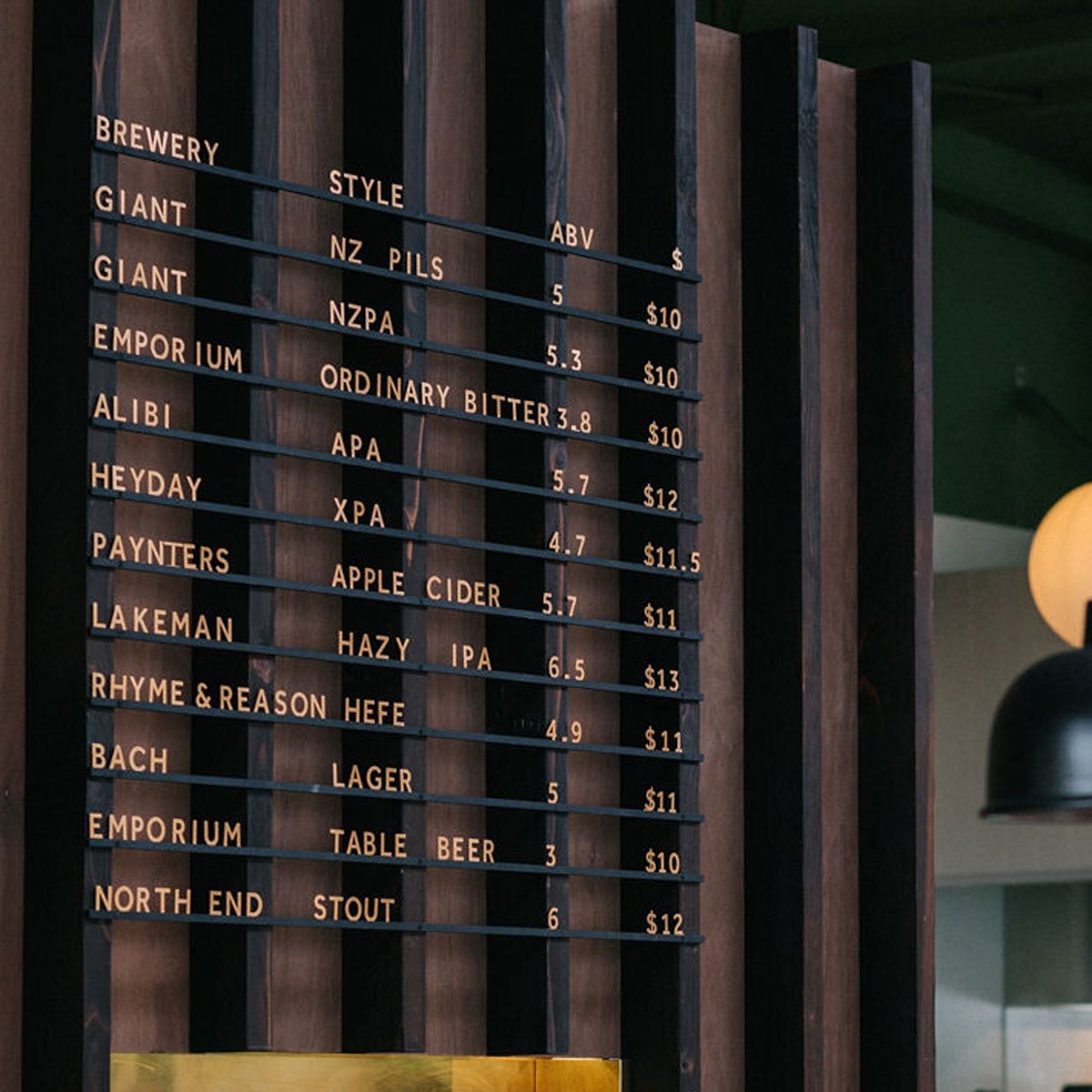

Your lightbox sign is a key piece of your brand identity. Using your brand’s logo, colors, and fonts consistently is crucial. A University of Loyola study found that using signature colors can increase brand recognition by up to 80%. When it comes to messaging, keep it simple. A business name and logo, or a name with a very short tagline like “Coffee & Bakery,” is often most effective. The “5 second rule” is a great guideline: if someone can’t understand your sign in five seconds, it’s too cluttered.

Many ready made signs, including those from George & Willy, arrive as a blank canvas, allowing you or a local signwriter to apply your unique branding with vinyl decals. This gives you the flexibility to get the perfect look while using professionally crafted hardware.

Font Selection and Graphics

Choosing the right font is critical for readability. Bold, sans serif fonts are generally best for signs because they are easy to read from a distance. A good rule of thumb is to use letters that are 1 inch tall for every 10 feet of viewing distance. So, for a sign meant to be read from 30 feet away, letters should be at least 3 inches high.

For graphics, high resolution images and crisp logos look fantastic when backlit. The illumination makes colors appear more vibrant and saturated, helping your sign stand out.

The Anatomy of a Lightbox Sign

Understanding the materials and components that go into a lightbox sign can help you appreciate its quality and durability.

Dimensions and Materials

Lightbox signs come in various standard and custom dimensions. The size you choose should depend on your location and how far away you want it to be seen. The frame is typically made of powder coated aluminum, which is lightweight, durable, and won’t rust, making it ideal for outdoor use.

The sign face is usually made from one of two plastics:

Acrylic: Known for its excellent clarity and stiffness, it produces sharp, vibrant images.

Polycarbonate (Lexan): While slightly less clear than acrylic, it is extremely impact resistant and better suited for very large signs or areas with high winds.

LED Selection

The heart of any modern lightbox sign is its LED lighting. High quality signs use high output LED strips or modules to ensure a bright and even glow. A neutral white color temperature (around 4000K to 4500K) is often preferred because it renders colors naturally. For outdoor signs, it’s essential that the LEDs are waterproof, with at least an IP65 rating to protect against dust and rain.

From Assembly to Installation

While many businesses opt for professional installation, understanding the assembly process is helpful. For those who enjoy a good DIY project or are simply curious, the process generally involves preparing components, assembling the frame, installing the lighting, and securing the panels.

Component and Frame Preparation

This stage involves cutting all materials (frame pieces, back panel, acrylic sheet) to the correct size, smoothing any rough edges, and pre drilling holes for fasteners. Painting the interior of the box white is a common pro tip, as it helps reflect and diffuse the light for a more even illumination.

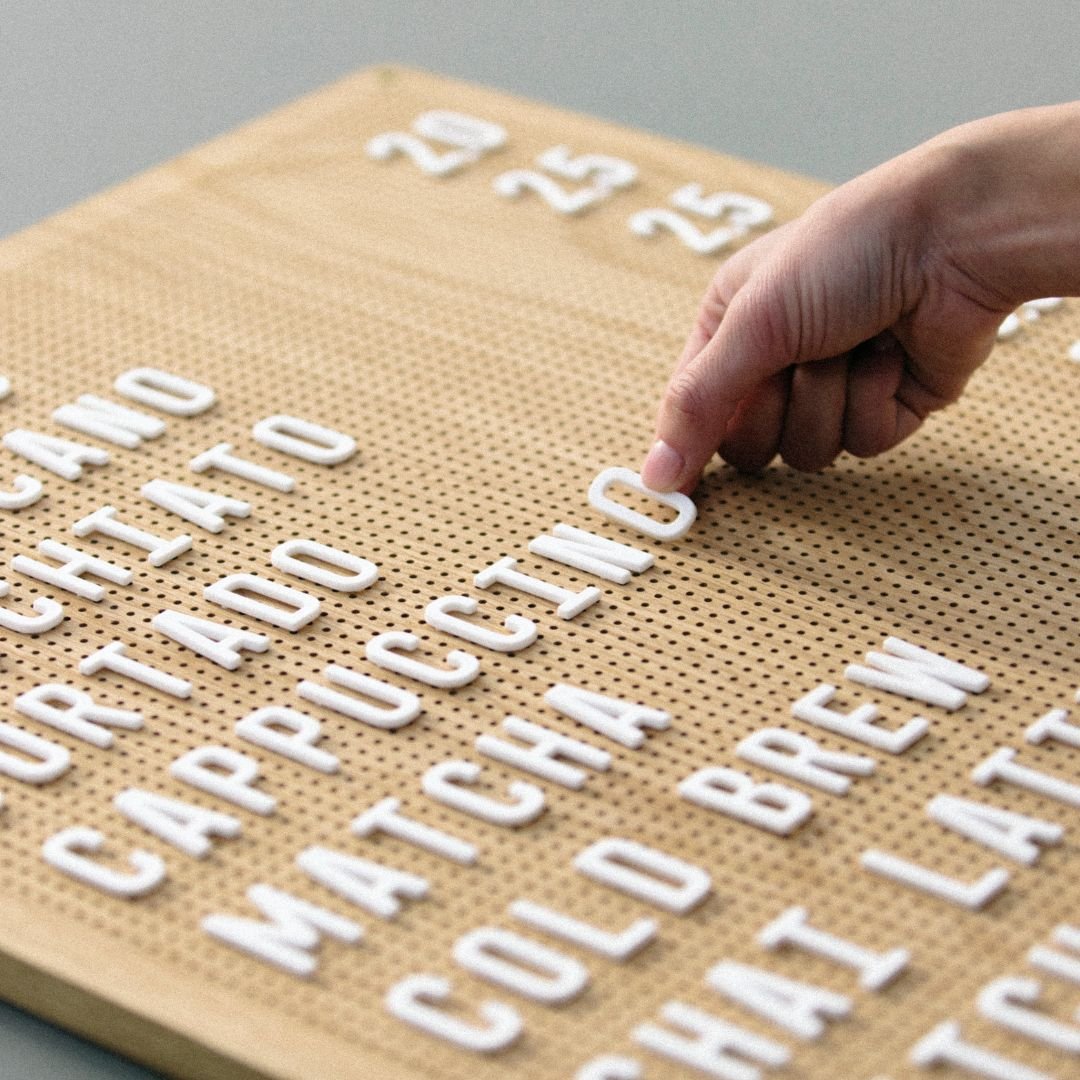

Assembly and LED Mounting

Once the parts are ready, the frame is assembled. Next, the LED strips or modules are mounted inside, either along the edges (edge lit) or on the back panel (back lit). It’s a good idea to test the LEDs at this stage to make sure everything is working before sealing up the sign. Finally, the acrylic face with the graphic is affixed, and the back panel is secured, completing the enclosure.

Powering and Mounting Your Sign

Most lightbox signs run on safe, low voltage power (12V or 24V) and come with a power adapter that plugs into a standard wall outlet. Some signs, like the George & Willy Curve Light Box Sign, are designed for simple plug and play installation.

Mounting the sign securely is the final step. This can be done flush against a wall or, for double sided signs, on a projecting bracket. Always use hardware that is appropriate for your wall type (e.g., masonry anchors for brick) and ensure the sign is level.

Care, Troubleshooting, and Strategy

A lightbox sign is a long term investment, and with a little care, it will serve your business well for years.

Maintenance and Cleaning

Keeping your lightbox sign clean is simple. Periodically wipe the acrylic face with a soft cloth and a mild soap and water solution to keep it looking fresh and shining brightly. It’s also a good idea to annually check that mounting hardware is tight and inspect for any signs of wear.

Troubleshooting Common Issues

If your sign ever has issues, troubleshooting is often straightforward.

Sign not lighting up? Check the power source and circuit breaker first. If that’s not the issue, the power supply (or driver) may need to be replaced.

Flickering lights? This can indicate a loose connection or an overloaded power supply.

Part of the sign is dark? There may be a break in the wiring or a failed LED segment. Always disconnect the power before opening the sign to inspect the wiring.

Placement and Exposure Strategy

Where you place your sign matters. Position it in a clear line of sight for your target audience. For pedestrian traffic, a projecting double sided lightbox sign can be extremely effective. Pair it with an A‑Frame Sign on the sidewalk to capture attention at street level. Studies have shown that strategically placed signs can increase customer recall by over 35%. Consider height, viewing angles, and potential obstructions like trees to ensure your sign gets the maximum exposure possible.

Applications and Cost

The versatility of the lightbox sign makes it a popular choice across countless industries.

Common Applications

You will find lightbox signs used for:

Retail Storefronts: For branding and visibility.

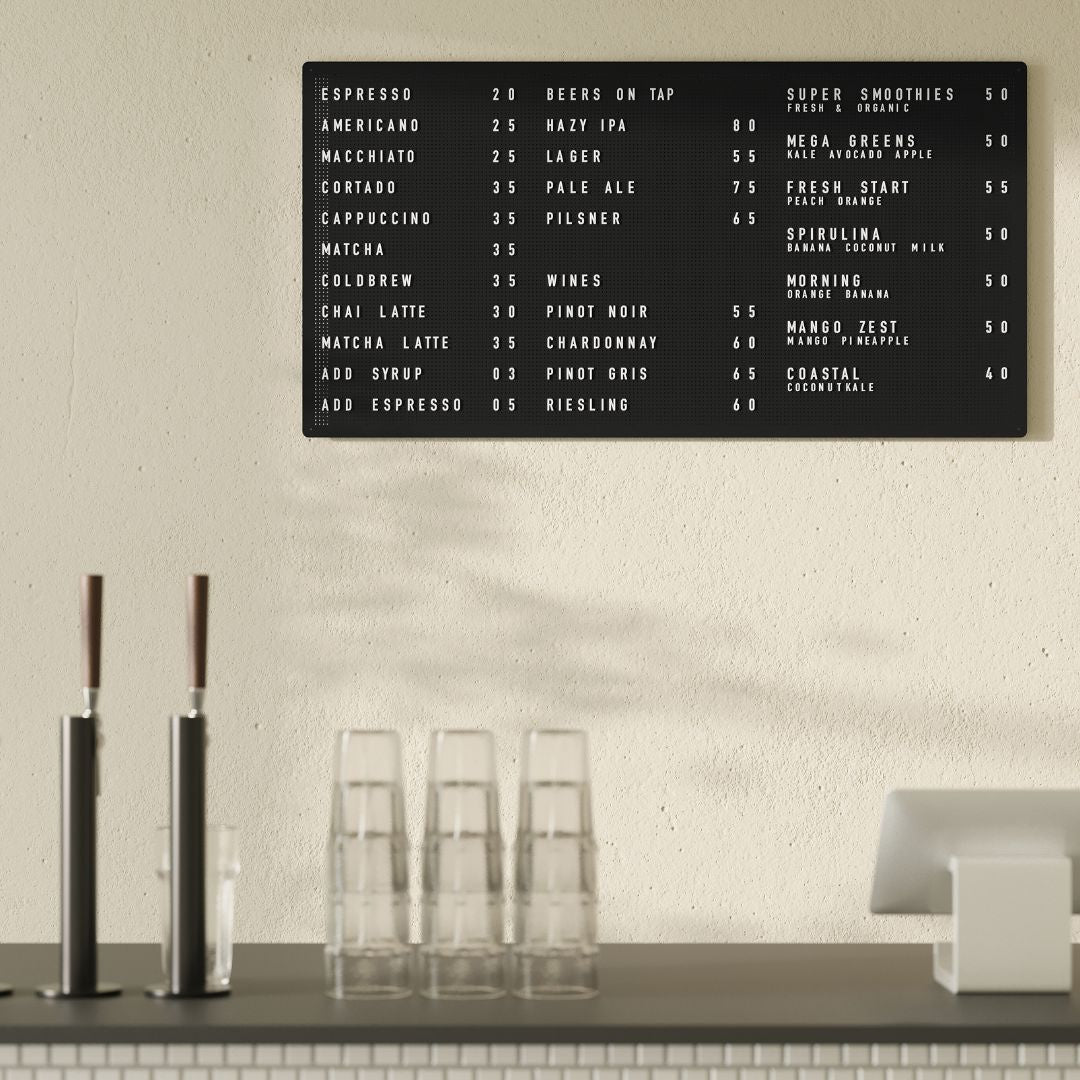

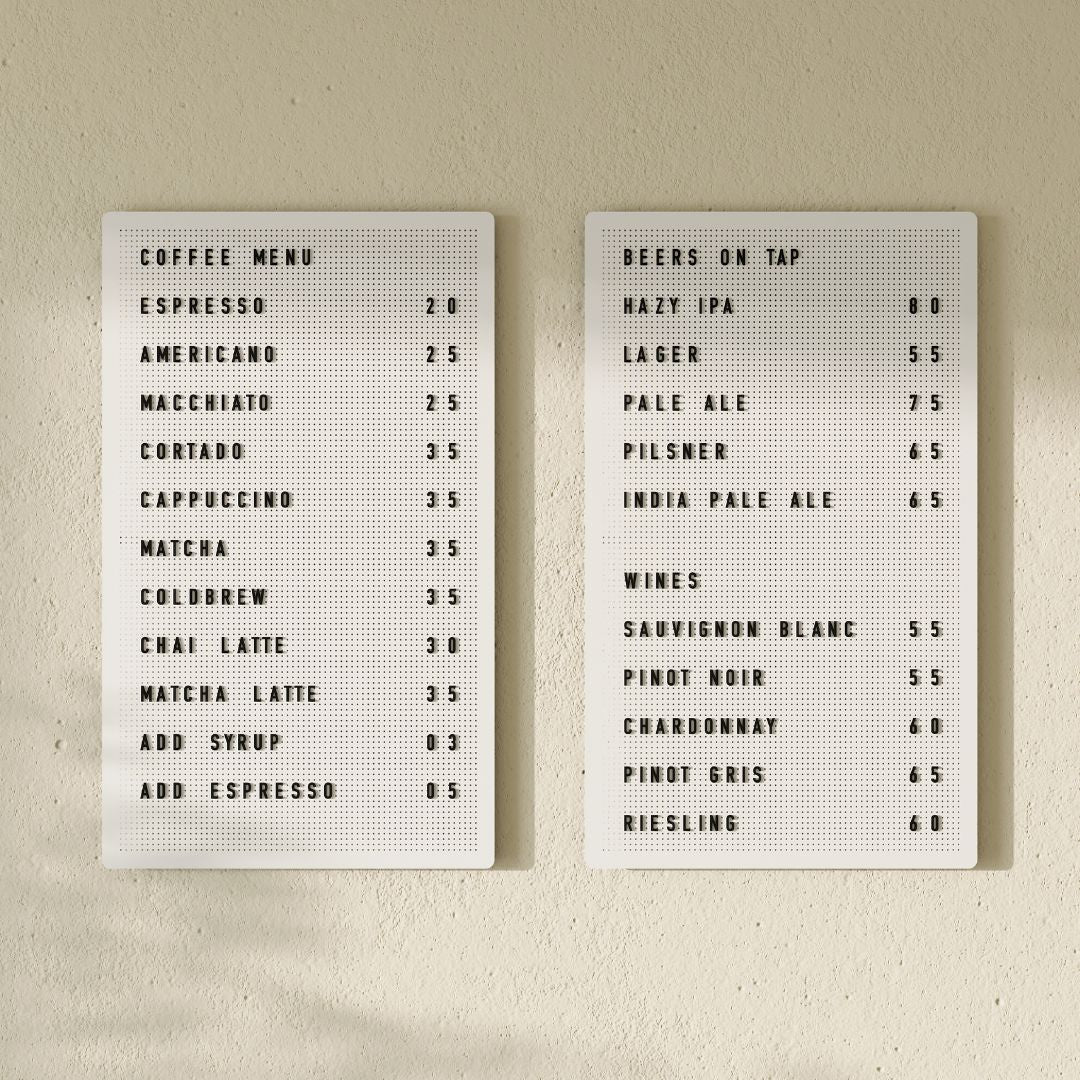

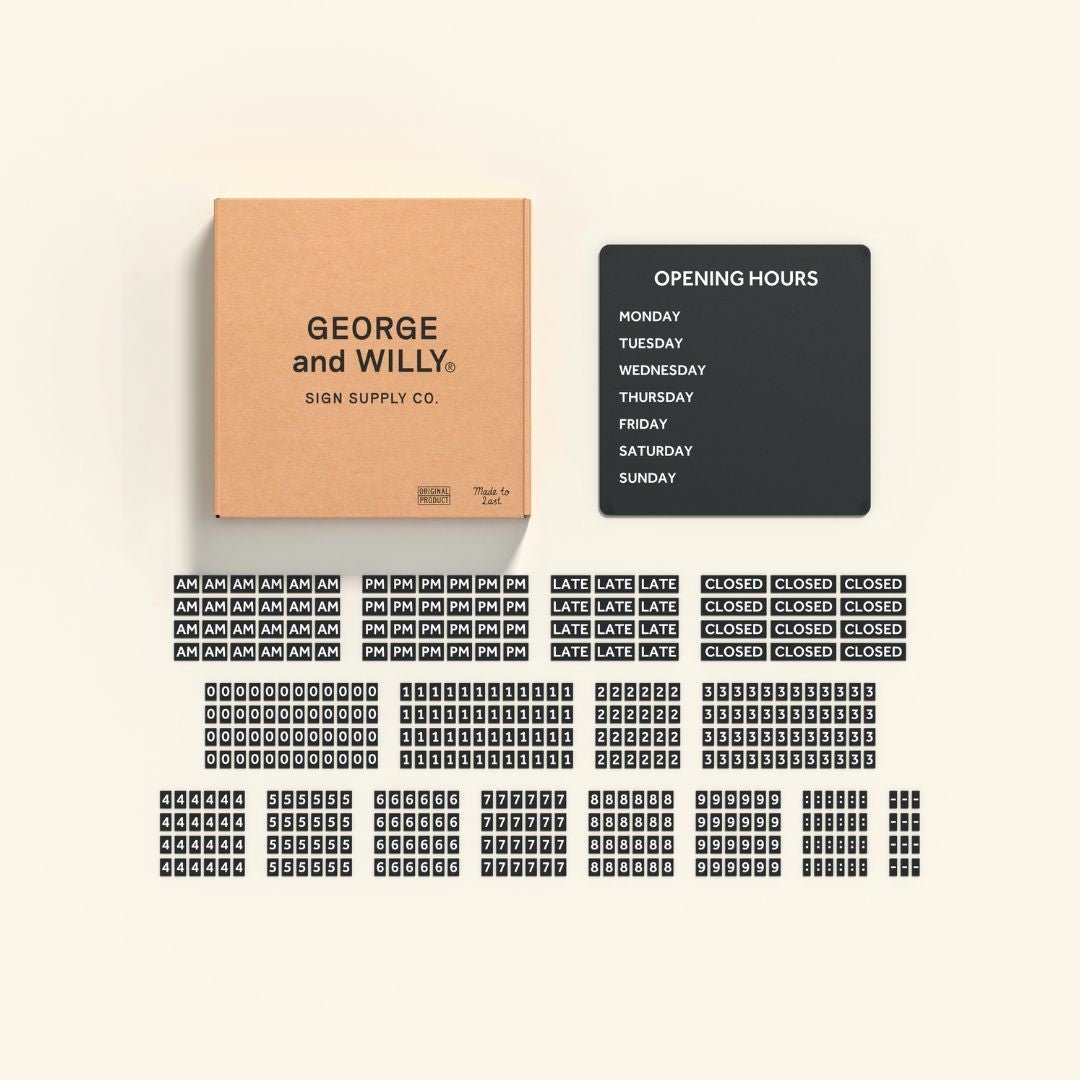

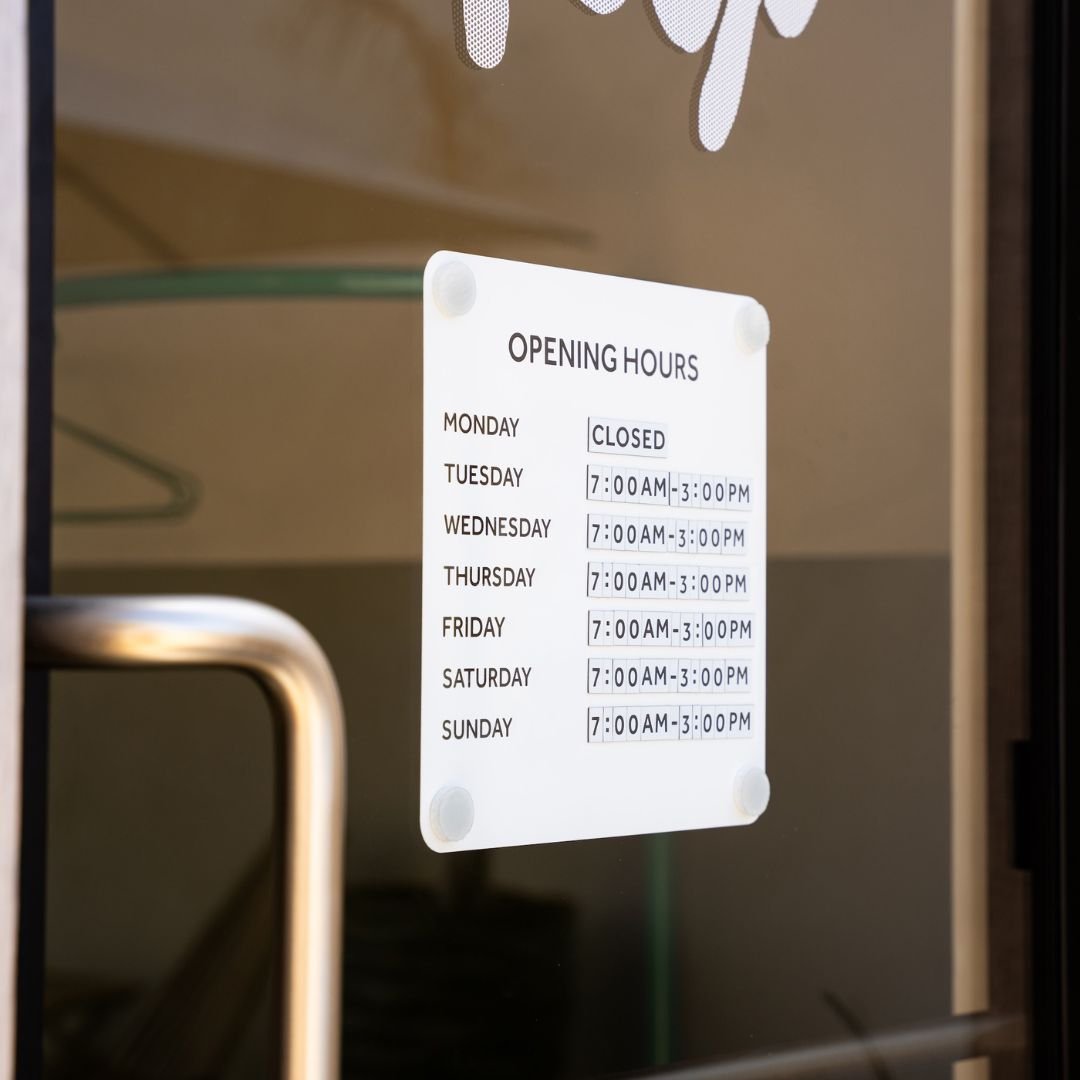

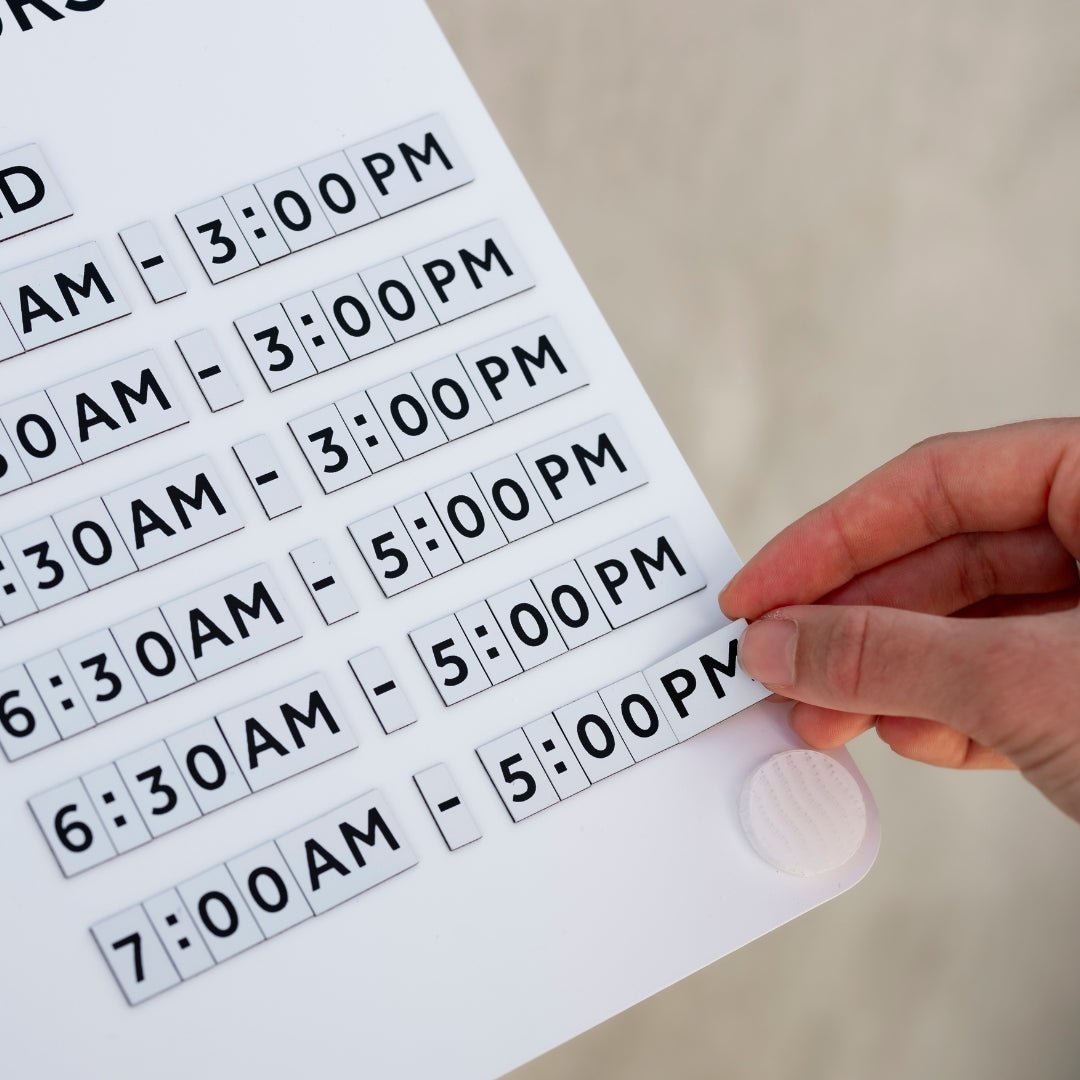

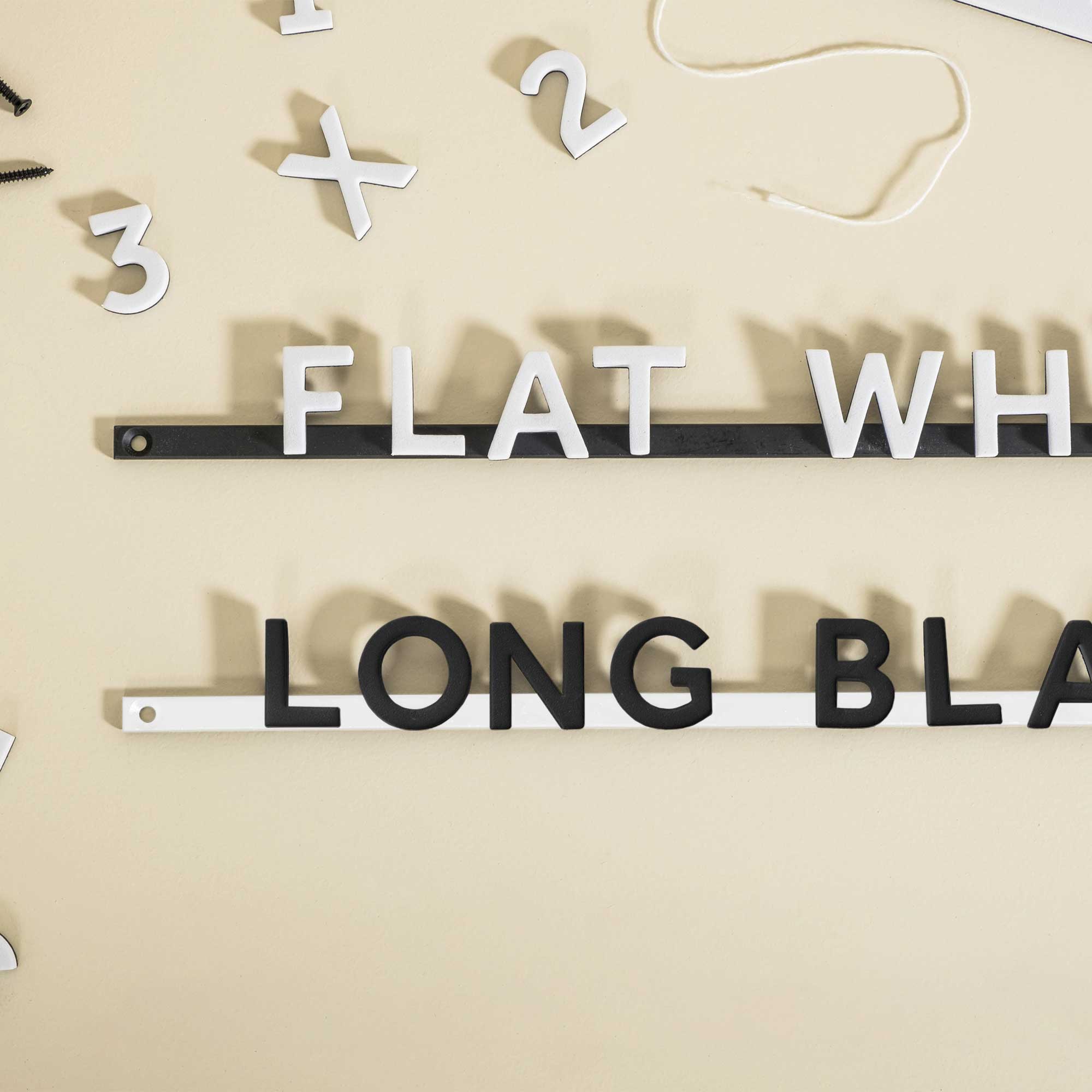

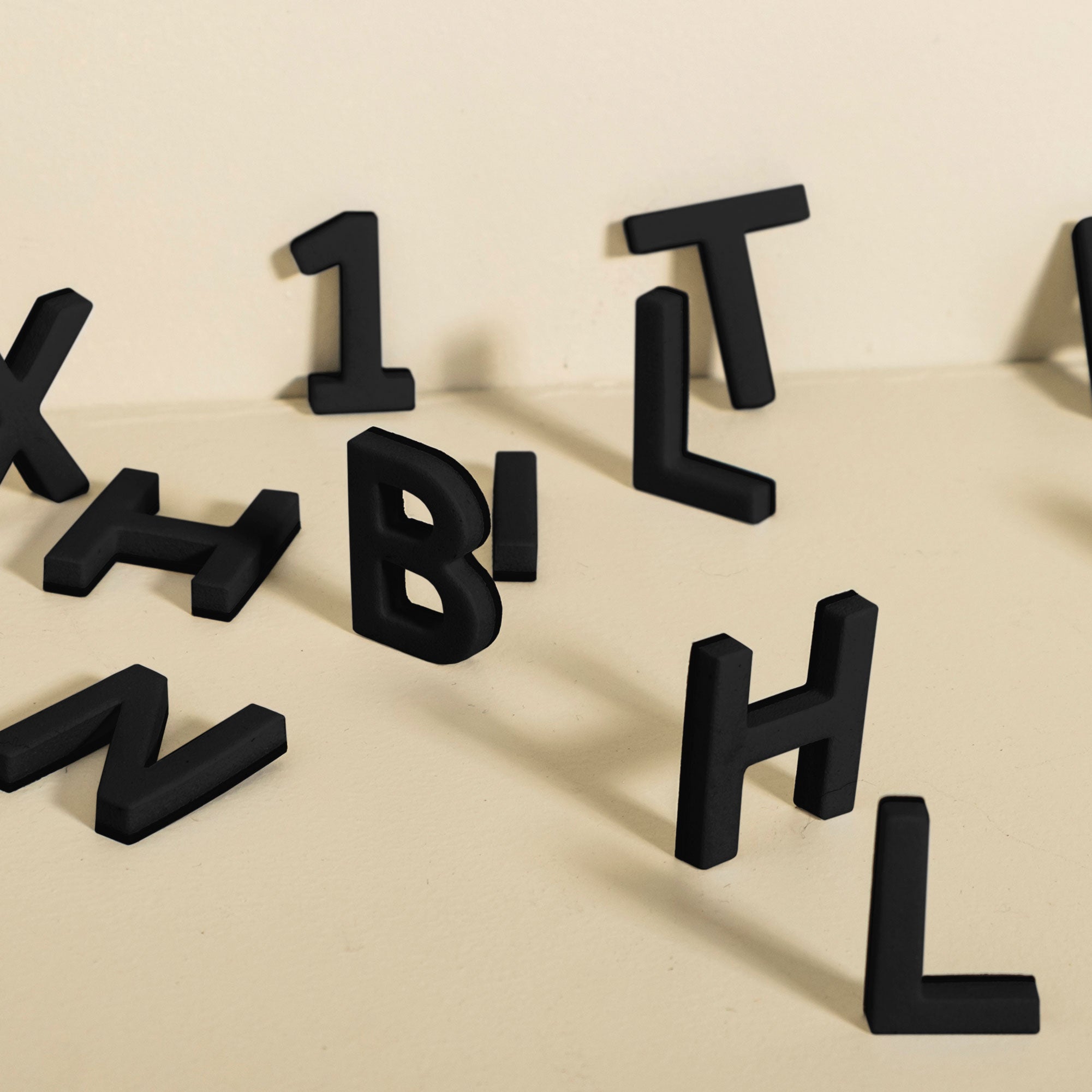

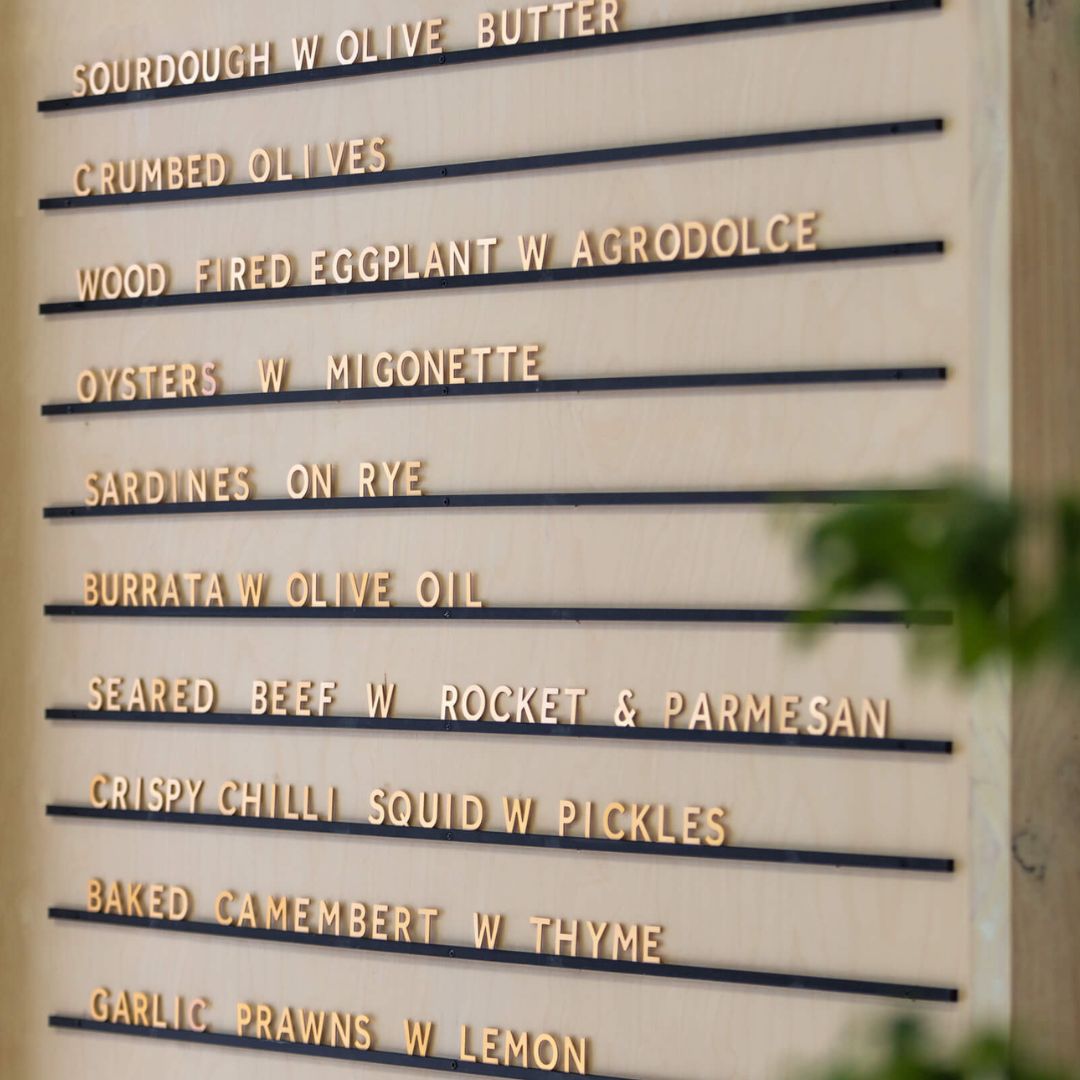

Restaurants and Cafes: As exterior signs and interior menu boards such as a Magnetic Letter Menu Board.

Hospitality: For hotels, motels, and reception areas. Pair with Counter Signs to keep front desks tidy and on‑brand.

Trade Shows: Portable fabric lightboxes make for stunning backdrops.

Wayfinding: In airports, malls, and hospitals where a Square Panel Sign offers clear identification.

What Does a Lightbox Sign Cost?

The cost of a lightbox sign varies based on size, materials, and complexity. A small, off the shelf sign might cost a few hundred dollars. Custom, medium sized storefront signs typically range from $1,500 to $3,000. Factors that influence the price include:

Size: Larger signs require more materials and labor.

Shape: Standard rectangles and circles are more affordable than custom shapes.

Materials: Durable materials like polycarbonate can increase the cost.

Double Sided: A double sided sign can cost 60% to 100% more than a single sided version.

For a high quality, design focused solution without the full custom price tag, brands like George & Willy offer stylish options like their Round Light Box Sign, which provides an accessible entry point for businesses looking to elevate their presence.

Lightbox Sign FAQ

Are lightbox signs suitable for outdoor use?

Yes, most quality lightbox signs are designed to be weatherproof. Look for signs made with powder coated aluminum frames and sealed construction to protect against the elements. It’s also important that the internal LEDs have a waterproof rating, like IP65. For simple open/closed messaging to complement your storefront lightbox, an Open Sign is a great add‑on.

How long do lightbox signs last?

A well made lightbox sign can easily last for over a decade. The LED lights are typically the first component to age, and they are rated for 50,000 to 100,000 hours of use, which translates to many years of reliable operation.

Are lightbox signs energy efficient?

Absolutely. Modern lightbox signs that use LEDs are very energy efficient. They consume up to 80% less electricity than older signs that used neon or fluorescent bulbs, making their impact on your power bill minimal.

Can I change the graphic on my lightbox sign?

Yes. Most lightbox signs are designed to allow for graphic updates. On signs with an acrylic face, you can typically replace the vinyl decal or the entire acrylic panel. Fabric signs are even easier, allowing you to swap out the printed fabric graphic in minutes.

Do I need a professional to install my sign?

For smaller, plug in signs, a confident DIYer can often handle the installation. These signs can be as simple to mount as a heavy picture frame. However, for larger signs or any sign that requires hardwiring into your building’s electrical system, it is always recommended to hire a professional electrician or sign installer for safety and peace of mind.