Industrial signage refers to the collection of signs, labels, and visual cues used throughout manufacturing plants, warehouses, and other industrial settings. In any busy facility, from a sprawling distribution center to a high-tech manufacturing plant, these signs are the unsung heroes of safety and efficiency. More than just a compliance requirement, a smart industrial signage strategy keeps people safe, guides workflow, and even sharpens your brand’s professional image. With workplace injuries remaining a significant concern, the right signs can make all the difference.

This guide explores how to build a robust industrial signage system that protects your team and boosts your bottom line.

Why Your Industrial Signage Strategy Matters

Effective signage is a powerful tool for preventing accidents. Considering an estimated 70% of workplace incidents are linked to human error, a well placed sign can be the critical reminder that prevents a costly mistake. Businesses lose billions each year due to avoidable safety failures, yet a strong signage program is a relatively low cost solution. Studies have shown that a well implemented system can reduce incident rates by 30 to 50% in high risk environments. The goal is to create a visual language that communicates clearly and instantly, turning your facility into a safer, more productive space.

The First Step: An Industrial Signage Needs Assessment

Before you order a single sign, start with a thorough audit. This is your industrial signage needs assessment. Walk through your entire facility, both inside and out, and map out every location that requires a sign. Think about hazard warnings, directional guides, safety reminders, equipment labels, and exit routes.

Involve your safety team to ensure you cover all bases and comply with regulations. OSHA, for example, mandates that warning signs be posted wherever serious hazards exist, using standardized designs that convey danger quickly. Failing to post required signs can lead to citations. This initial assessment creates the foundation for a truly effective system.

Tailoring Signage for Your Unique Facility

One size does not fit all when it comes to industrial signage. Every facility has unique layouts, hazards, and people, so your signs should be tailored to your specific environment.

Language and Comprehension: For a multilingual workforce, use signs with both text in multiple languages and universally understood pictograms. This simple step can improve safety compliance by 40%. Be aware that some symbols are not as universal as you might think. One study found that less than 40% of workers understood the generic icon for toxic materials, so adding text is often a good idea.

Environmental Factors: In dimly lit areas, photoluminescent (glow in the dark) or backlit signs are essential for visibility. For outdoor use, choose materials that can withstand the elements without fading or deteriorating.

Essential Signage for Manufacturing Floors

On the manufacturing floor, signs pull double duty, enhancing both safety and productivity. This is where clear manufacturing signage has a measurable impact.

For safety, prominently display Danger and Warning signs near high voltage areas or heavy machinery. A simple “Danger: High Voltage” sign has been shown to cut electrical accidents by 15% in industrial settings. Machine specific warnings about hot surfaces or moving parts are also crucial.

For productivity, embrace visual management. Use 5S principles with clear labels, tool shadow boards, and color coded floor markings to eliminate confusion. One case study revealed that implementing a 5S visual system, which relies heavily on signs and labels, led to an average productivity increase of 32%.

Mastering Signage for Distribution Centers and Industrial Properties

Sprawling warehouses and distribution centers present their own unique challenges. With the average warehouse covering a massive 672,000 square feet, effective wayfinding is not a luxury, it’s a necessity.

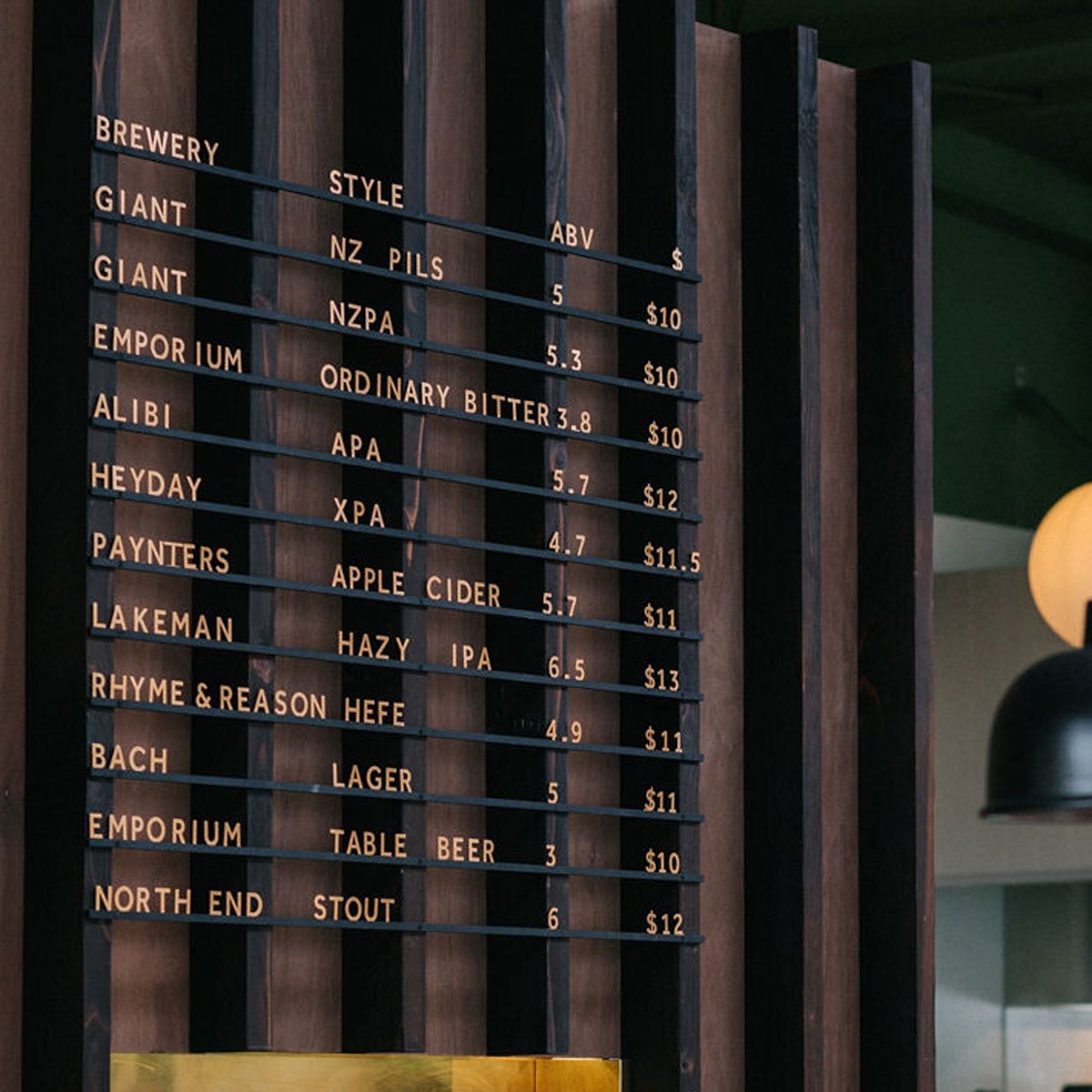

The right type of sign for an industrial property and distribution center includes:

Wayfinding Signage: Clear aisle markers, dock door labels, and suspended directional signs help workers and drivers navigate efficiently. Since walking can account for 50% of order picking time, optimizing routes with clear guidance directly impacts your bottom line.

Exterior and Yard Signage: Use large, visible building numbers so trucks can find the right loading bay. Standard traffic signs like stop, yield, and speed limit are essential for yard safety. Add safety reminders like “Pedestrian Crossing” or “High Vis Vest Required Beyond This Point” where needed.

A thoughtful mix of signs creates an organized environment where people and products move smoothly.

Boost Your Brand with Custom Building Signage

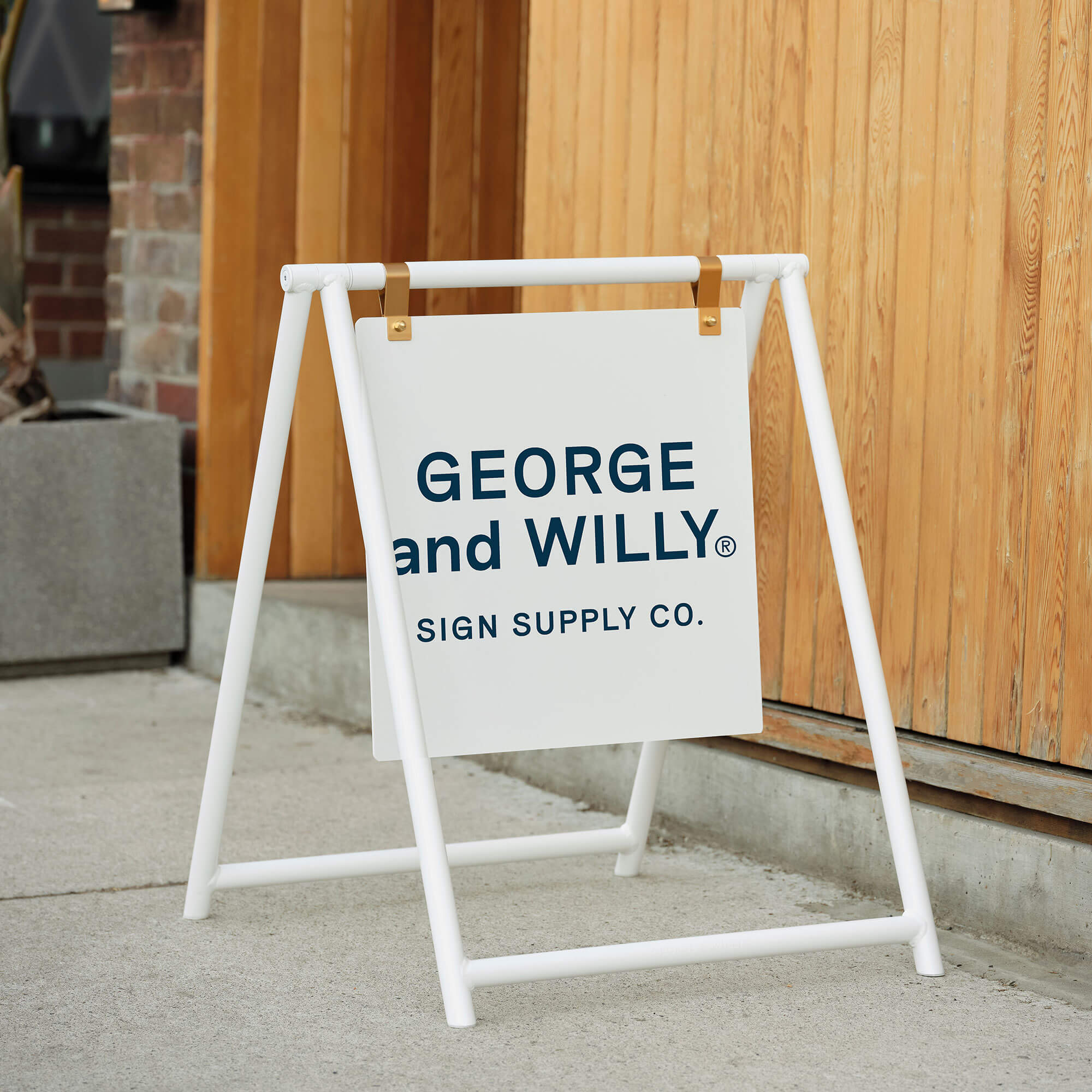

Don’t overlook your exterior signage as a branding opportunity. For example, a Round Outdoor Shop Sign can make a clean first impression. A custom sign on your building is often the first impression a visitor, partner, or potential new hire has of your company. Research shows that nearly 70% of consumers believe a business’s signage reflects the quality of its products or services.

A faded or poorly maintained sign can turn people away. In contrast, upgrading your signage can have a positive impact on business, with some companies reporting an average revenue increase of 10% after a revamp.

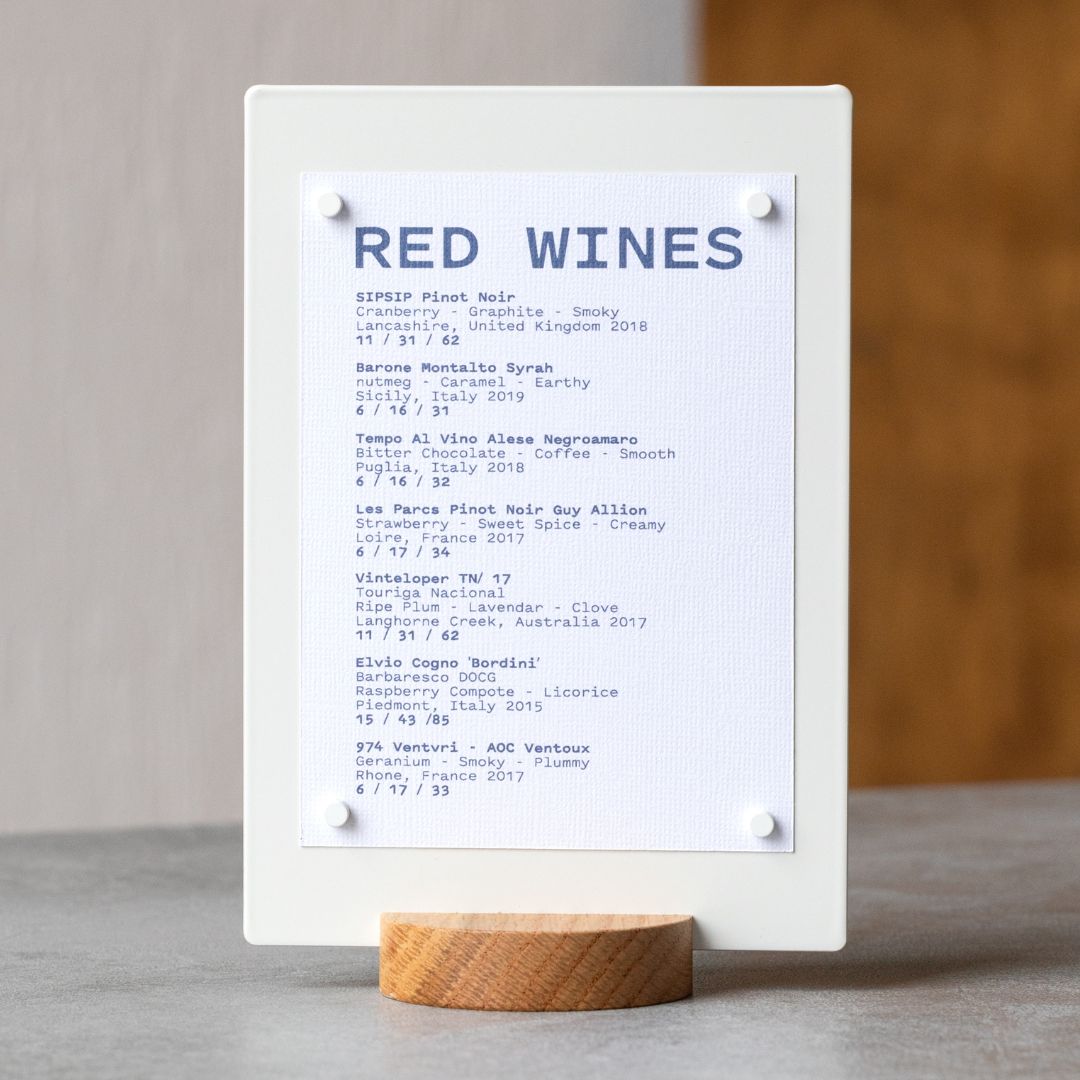

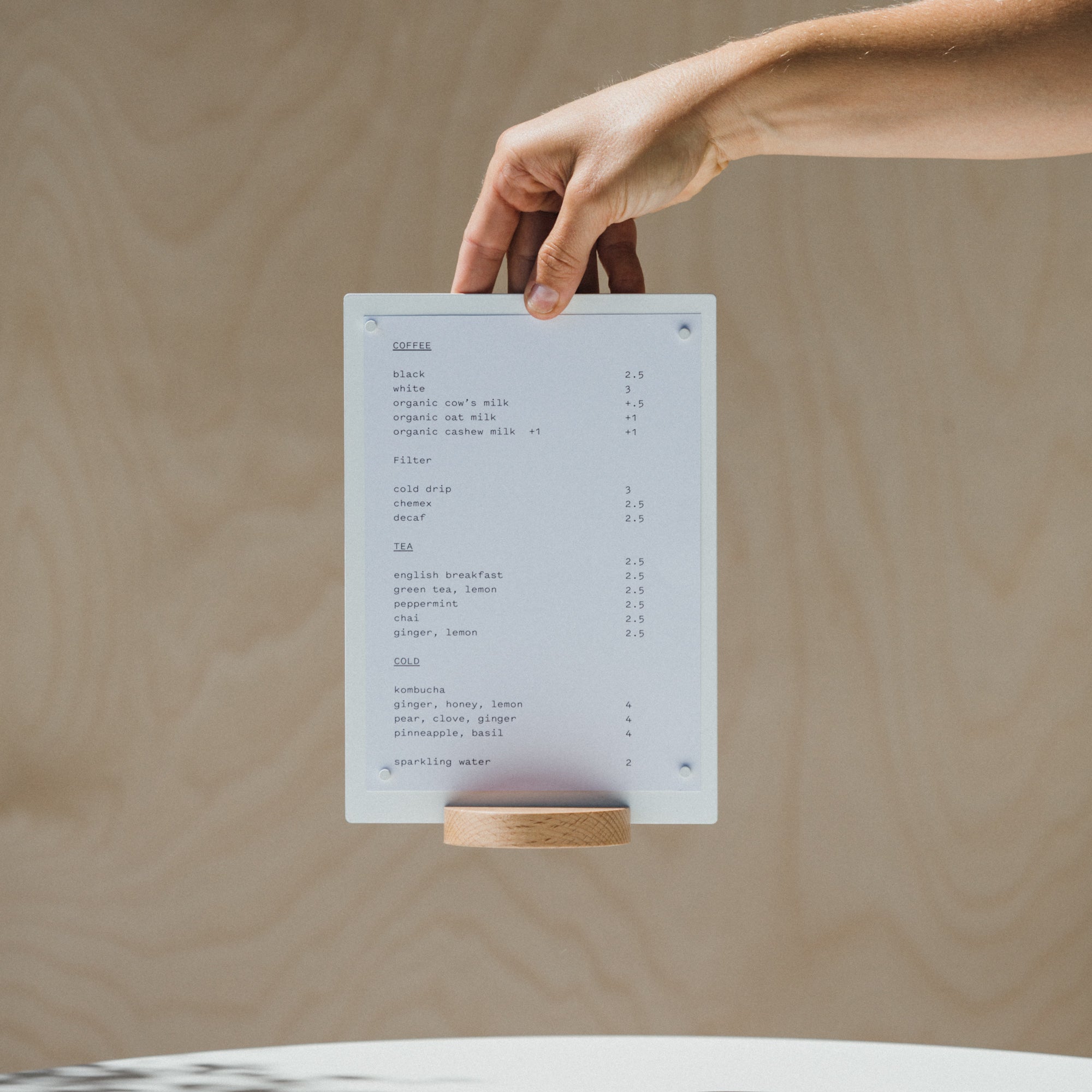

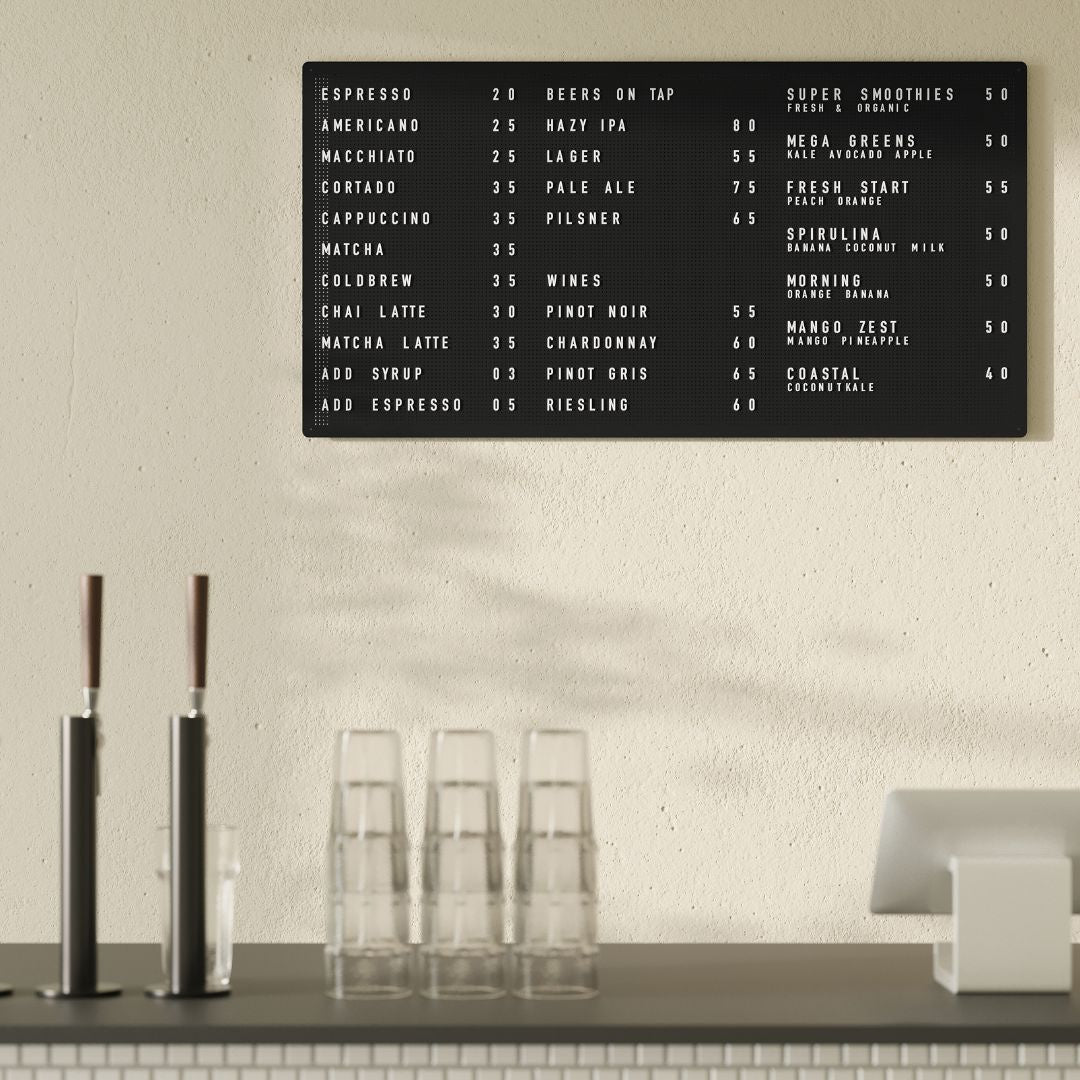

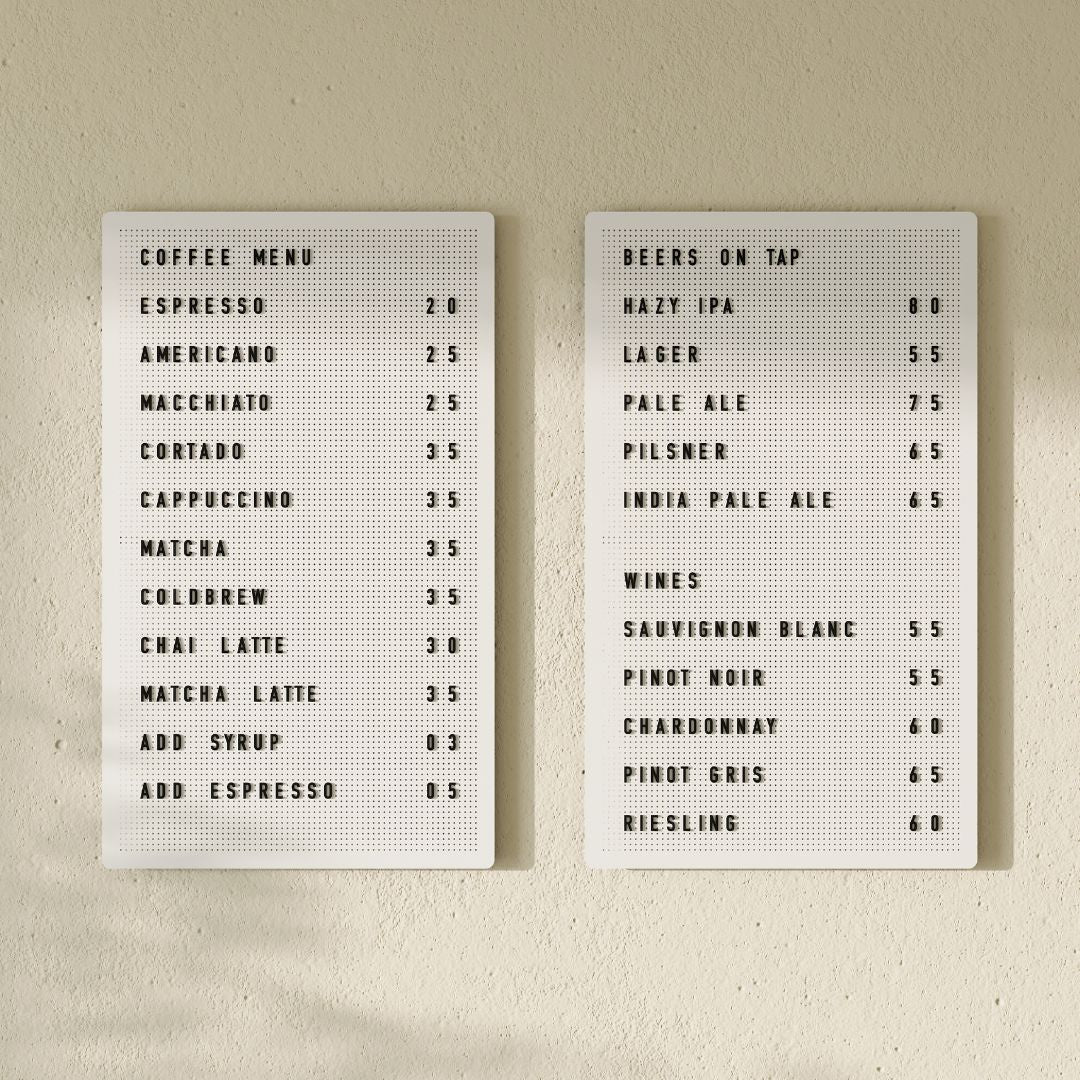

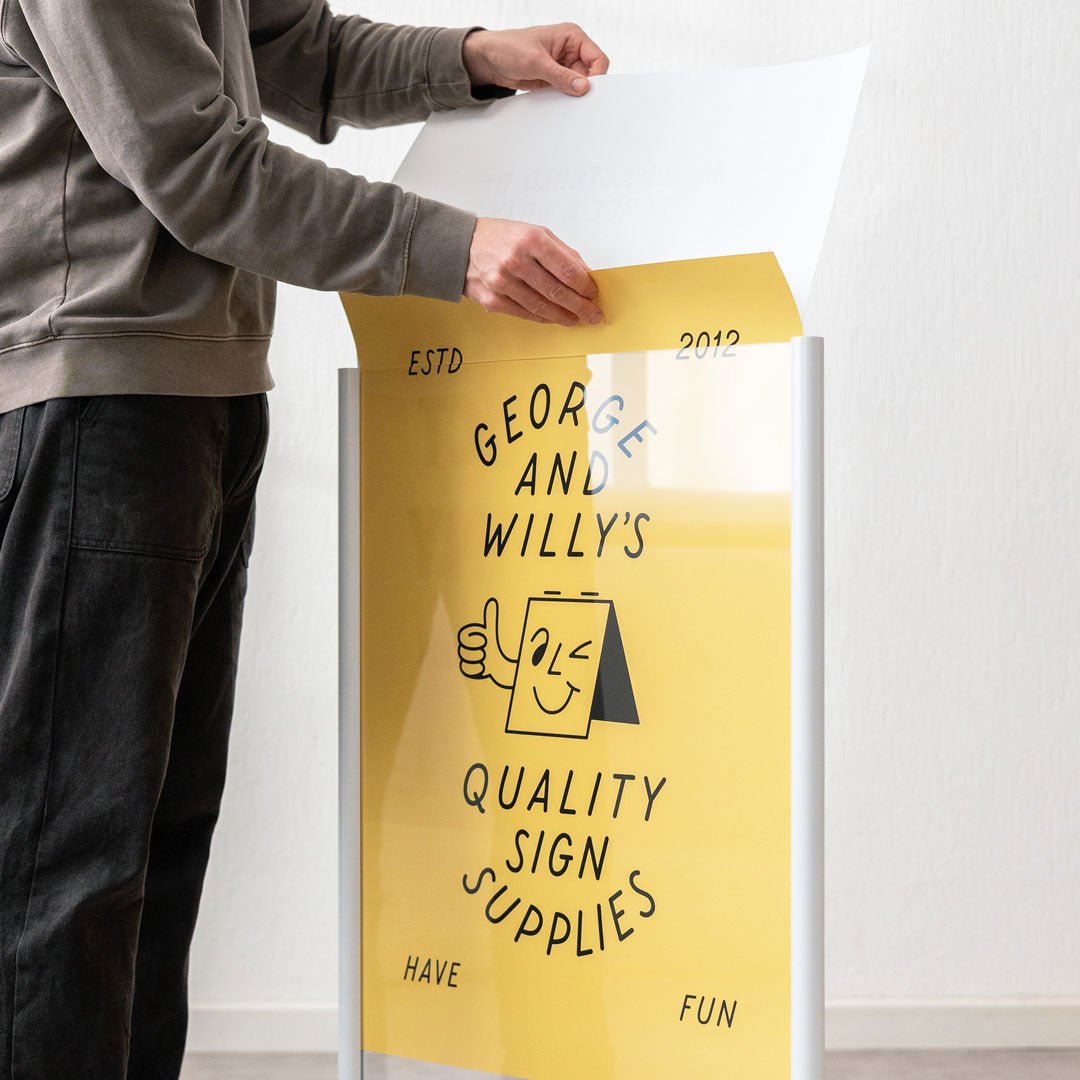

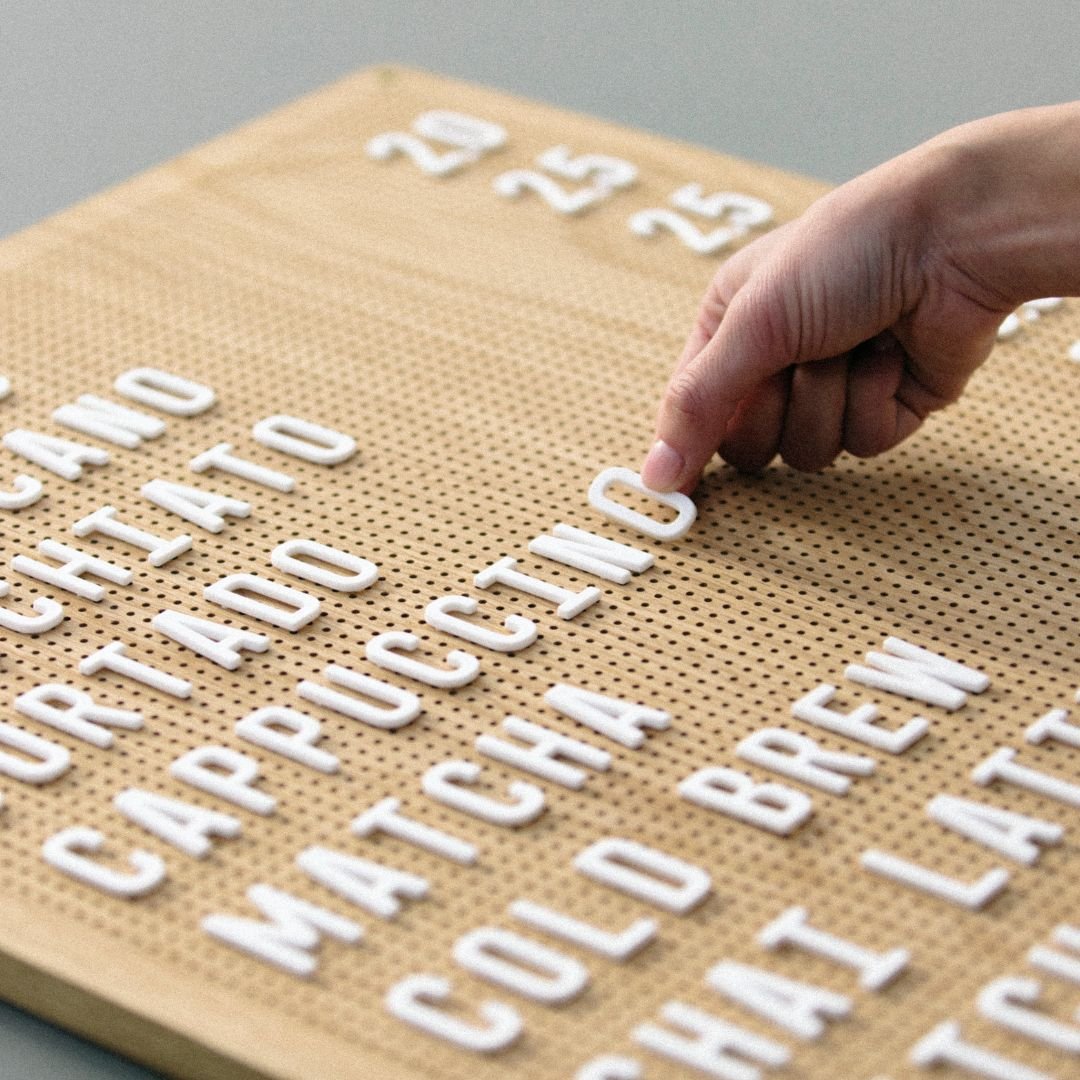

Your custom signage for your building should be clean, professional, and consistent with your brand colors and logo. For a polished look without the long lead times of bespoke fabrication, many businesses choose a high quality blank sign, like a modern A-Frame Sign, and have a local signwriter apply their vinyl logo.

Key Industrial Signage Tips for Maximum Impact

Once you have a plan, focus on execution. A few core principles can make your industrial signage program much more effective.

Choose Durable, Compliant Materials

Industrial environments are tough, so your signs need to be too. Opt for durable materials like powder coated aluminum, which resists rust and stands up to sun and rain (for example, a Rounded Sidewalk Sign built from powder-coated aluminum holds up outdoors). It is a key industrial signage tip to invest in quality from the start. Also, ensure your signs meet all relevant OSHA and ANSI standards for colors, fonts, and pictograms. These standards exist because they have been proven to communicate warnings effectively at a glance.

Keep It Clear, Consistent, and Intuitive

Clarity is everything. Use legible fonts, high contrast colors, and simple language. Visuals are powerful, as the brain can process images up to 60,000 times faster than text. A clean pictogram or color cue will transmit its message almost instantly. Maintain consistency in your designs and placement so employees learn where to look for important information.

Train Your Team for Effective Industrial Signage Use

The best signs are useless if your team doesn’t understand them. Make training on industrial signage use a part of your onboarding and regular safety meetings. Studies have found that without training, employees may only correctly interpret two thirds of common safety signs. OSHA actually requires employers to instruct their teams on the meaning of specific signs, such as ensuring everyone knows that a “Danger” sign indicates an immediate hazard requiring special precautions.

Review and Improve Your Signage Strategy Continuously

Your facility is always evolving, and your industrial signage should evolve with it. Don’t treat signage as a one time project. Periodically review your signs to ensure they are still accurate, visible, and relevant. After any near miss or incident, ask if better signage could have helped prevent it.

By continuously improving your signage, you are not just protecting your team, you are protecting your business. Companies with fully compliant signage have been shown to have 50% fewer legal disputes related to workplace accidents. If you are looking for timeless, durable options that can adapt as your business grows, explore a collection of thoughtful signage solutions, such as a Standing Round Sign for entry points.

Frequently Asked Questions About Industrial Signage

What is industrial signage?

Industrial signage refers to the signs, labels, and visual cues used in manufacturing plants, warehouses, distribution centers, and other industrial facilities. Its primary purpose is to convey information related to safety, navigation, and operational procedures to employees, visitors, and contractors.

Why is industrial signage so important for safety?

It is crucial for safety because it provides immediate visual warnings about hazards like high voltage, moving machinery, or chemical exposure. This helps prevent accidents and injuries. Well placed signs can reduce workplace incidents by alerting workers to potential dangers before they become a problem.

What are the main types of industrial signage?

The main types include safety signs (danger, warning, caution), directional and wayfinding signs (aisle markers, exit signs), identification signs (equipment labels, door numbers), and informational signs (policy reminders, quality control instructions).

How do I choose the right materials for industrial signs?

Choose materials based on the environment. For outdoor or harsh indoor conditions, durable, weather resistant materials like powder coated aluminum or stainless steel are ideal. For areas with low light, consider photoluminescent or reflective materials.

Are custom industrial signs worth the investment?

Yes, especially for exterior building signage. A custom sign reinforces your brand identity and professionalism. Statistics show nearly 70% of consumers judge a company’s quality by its signage, making it a worthwhile investment in your brand’s image.

How often should I review my facility’s signage?

It is a good practice to review all industrial signage at least once a year, or whenever there is a change in your facility’s layout, equipment, or processes. You should also review signage after any safety incident or near miss to see if improvements can be made.